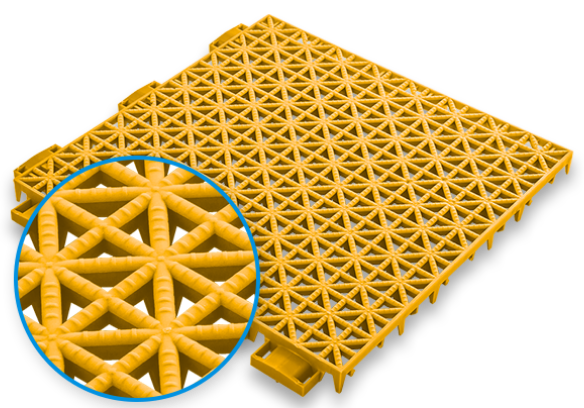

Interlocking Garage Floor Tiles

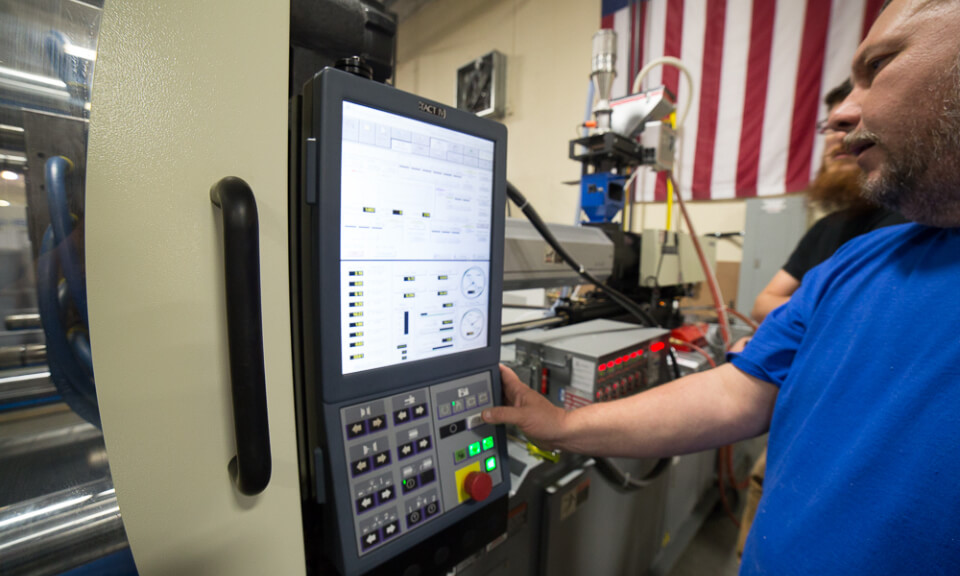

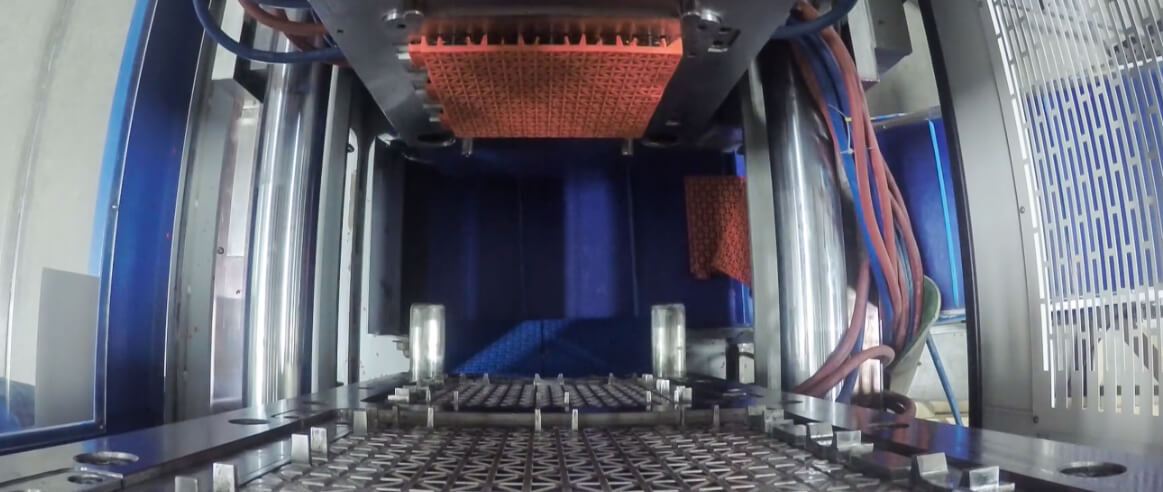

At VersaCourt, we are constantly striving to improve our processes and provide the most innovative products to our customers. This year, we continued to innovate our process with the installation of two advanced, fully-electric injection molding presses at our production facility in Dalton, GA.

From the beginning, it has been VersaCourt’s mission to become the industry leader in the design and production of advanced court tile solutions. We started with a company pledge to always stay on the cutting edge of technology and use only the highest-quality materials to ensure optimal product performance for our customers. After years of production, we have kept to our pledge and look to be the standard in the industry.

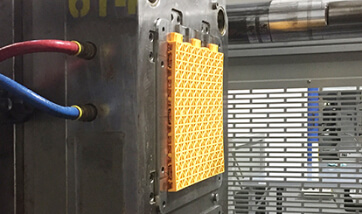

Our new fully electric injection molding presses drastically cut down on our overall production time, while maintaining the integrity and reliability of VersaCourt tile solutions that our customers have grown to expect.

While improving our production process is very important to our company, we also want to make sure that we are improving our manufacturing capabilities in an environmentally responsible way.

VersaCourt utilizes an industry-leading process whereby each court is pre-assembled, painted and checked for quality, flatness and color consistency prior to shipment. The process is primarily used to simplify installation and ensure quality, but it has also helped the VersaCourt team identify any small imperfections or slight fluctuations in color. While these issues could be addressed prior to shipment, doing so required additional assembly time to replace tiles.

A gravimetric dosing system replaced the current volumetric dosing system improving the color consistency of each tile and reducing the overuse of expensive colorants.

A move to state-of-the-art electric injection molding presses reduced overall power consumption during the manufacturing process by up to 70% compared with previous hydraulic systems.

An innovative closed loop process cooling system was employed to decrease cycle time while greatly reducing energy costs.

All molds were cleaned and adjusted to improve both cycle time and quality.

Robotics were installed to increase productivity and provide more dependable cycle times.

A manufacturing process which empowers its team members to focus on quality and continual improvement was employed.

While VersaCourt’s end customers continued to enjoy the same quality courts that they were accustomed to, the manufacturing process was able to achieve nearly perfect color consistency while reducing the overall cost of the tile and eliminating re-work during the initial assembly process.

To learn more about our new technology, you can read our published press release, or watch the quick video above to see our equipment in action.

Anyone can claim that they are a world-class processor, but we are proud of the fact that Plastics Technology Magazine selected our team as one of its Top 25 processors in the world.